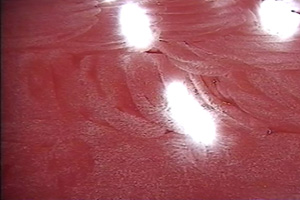

Pharmaceutical Factory Resin Terrazzo Floor

Red and Yellow terrazzo floors installed into Pharmaceutical factory

Description

This extensive project was to install a specialist red resin terrazzo floor in a pharmaceutical factory, south of London. This project ran on for several months, covering an estimated 7000m2 of floor over two different rooms. First was a red floor which the client was very happy with, resulting in us completing a second floor in a yellow colour.

Summary

Hygienic Environment

Red & Yellow Epoxy

Chemical & Stain Resistant

Brass seperator strips

Fully prepared slab & joints

Daytime working

Preparing Concrete

Comprehensive preparation works were undertaken on this large scale project. The existing slab was shotblasted free of contaminents and ground using 3 phase electric HTC floor grinding machinery.

Laying Terrazzo by Hand

Along edges, around columns and access covers we hand laid the red epoxy to an average depth of 10mm, ground down to 8mm finish. Surfaces were protected with low tack masking tape.

Sledging Resin Terrazzo

In large open areas we opted for sledging the terrazzo with weights keeping the sledge steady. This enabled us to have a constant supply of mix which meant we could lay more area than traditional hand trowelling.

Grinding & Polishing

Grinding was done with a mixture of 3 phase floor grinding machines including Blastrac, Asuga and HTC. Once the floor had been ground down flat, we then apply a grout, then polish the floor using water up to a finish of 400 grit. Around the edges and columns we used hand grinders and polishers.

Grouting

Grouting is used to fill any pinholes caused during the grinding phase. When mixing resin, air bubbles often get into the mix which are revealed when grinding the surface. This is addressed with a grout (same colour as the resin) which fills any air / pinholes and is usually of a creamy consistency to trowel down.

Sealing with PU Sealer

Once the floor has been ground, grouted and polished we finish with a thorough wash and seal using Polyurathane water based sealers. This helps protect from UV damage and also helps with abrasion resistance. To complete the process, we apply a high solids metallised floor polish and buff to finish.

More Resin Terrazzo Works

© 2018 Premfloor (Southern) Ltd - Phone: 0333 3055 147 - Email: info@premfloor.co.uk